压铸铝发黑、氧化、发霉的原因-羽杰科技

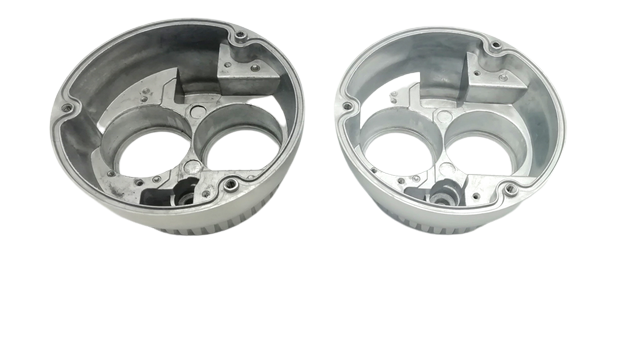

羽杰科技:压铸铝制品表面发黑,特别是在经过机加工以后会更加明显,表现为黑点黑斑。这种情况可能是压铸时压力不够,工件致密度不够,所以形成毛细孔,这些毛细孔吸水被氧化后就会出现这种问题。

The surface of die-casting aluminum alloy products is blackened, especially after machining, which is shown as black spots and black spots. This situation may It is because the pressure is not enough and the density of the workpiece is not enough during die casting, so pores are formed. This problem occurs after the pores absorb water and are oxidized

一铝合金压铸件发霉变黑的原因分析Cause Analysis of Mold and Blackening of an Aluminum Alloy Die Casting

其一,外部环境因素。铝是活泼金属,在一定的温度和湿度条件下极易氧化变黑或发霉,这是铝本身特性决定的。

First, external environmental factors. Aluminum is an active metal, which is easily oxidized and blackened or mildewed under certain temperature and humidity conditions, which is determined by the characteristics of aluminum itself.

其二,自身的内部因素。很多厂家压铸、机加工工序之后,不做任何清洁处理,或者简单的用水冲冲,无法做到彻底清洗干净,压铸铝表面残留有脱模剂、切削液、皂化液等腐蚀性物质,以及其他污渍,这些又加快铝合金压铸件长霉点;

Second, internal factors. After the die casting and machining processes, many manufacturers do not do any cleaning treatment, or simply flush with water, which can not be completely cleaned. The surface of die cast aluminum remains corrosive substances such as mold release agent, cutting fluid, saponification fluid, and other stains, which accelerates the growth of mold spots in aluminum alloy die castings;

其三,工艺设计不合理。铝合金压铸件在清洗或压检后处理不当,为铝合金压铸件发霉创造了条件,加速霉变的生成;

Third, the process design is unreasonable. Improper treatment of aluminum alloy die castings after cleaning or pressure inspection creates conditions for aluminum alloy die castings to become mouldy and accelerates the formation of mouldy;

其四,选用清洗剂不得当。清洗具有强腐蚀性,造成压铸铝腐蚀氧化。其五,仓储管理不到位。存放仓库不同的高度时,发霉的状况也不同。

Fourth, the cleaning agent is inappropriate. The cleaning is highly corrosive, causing corrosion and oxidation of die cast aluminum. Fifth, warehousing management is not in place. When the storage warehouse is at different heights, the mildew condition is different.

采取对策:从压铸铝发霉的原因分析,我们不难得出这样的结论:防氧化问题非单一因素造成的,他涉及内外部、工艺、仓储等多个方面。

同时清洗、压检、存放、运输等各个过程都需要考虑防氧化,哪个环节出现问题,都会长霉点给你看。故这是一个综合问题,需制定整体解决方案。

Countermeasures: From the analysis of the causes of mould forming of die cast aluminum, we can easily draw the conclusion that the oxidation prevention problem is not caused by a single factor, it involves internal and external, process, storage and other aspects.

At the same time, anti oxidation should be considered in all processes such as cleaning, pressure inspection, storage and transportation. If any problem occurs in any link, you will see the mildew. Therefore, this is a comprehensive problem, and an overall solution is needed.

羽杰科技从压铸铝清洗剂、压铸铝防氧化剂、工艺、存放环境、存放方式等角度出发,解决了铝合金压铸件发霉的难题,并可提供压铸铝清洗、压检、存放各个过程的防氧化解决方案。

From the perspective of die casting aluminum cleaner, die casting aluminum antioxidant, process, storage environment, storage mode, Yujie Technology has solved the problem of aluminum alloy die castings becoming moldy, and can provide anti oxidation solutions for all processes of die casting aluminum cleaning, pressure inspection, and storage.

本文标题:压铸铝发黑、氧化、发霉的原因-羽杰科技

原文链接地址:www.fangxiuoil.com/portal/article/index/id/258.html